Our company has ISO9001, API, SQ1 and other certificates, more than 80 sets of processing machinery and equipment, as well as ZEISS CMM, Japanese small plate profiler, gear detector, Ω MEGA tool setting instrument and other inspection and testing equipment.For the production of tubing hanger products, our company can independently design the mold according to the drawings provided by the customer, and use different materials according to the product specifications, through a series of processes such as rough machining, heat treatment, and finishing for mass production.

今連絡

Tubing connector is a tool to connect tubing and wellhead, which is usually used in oil exploitation and transportation projects. It connects tubing and wellhead closely to ensure the extraction and transportation of oil and gas resources. The tubing head connector is generally composed of two parts: the external thread of tubing thread and the internal thread of wellhead thread.NAMETubing Head ConnectorMATERIAL4130-75KHARDNESS207-237INNER DIAMETER65.41OUTSIDE DIAMETER504.95The tubing connector produced by our company is mainly used in oil field equipment accessories.

今連絡

Casing hanger is a device for supporting and fixing casing, which is usually used in drilling operations of oil wells and natural gas wells. It is located at the interface between wellhead and downhole casing, and plays the role of installing and maintaining casing.NAMECASING HANGERMATERIAL4140-130KHARDNESS301-341INNER DIAMETER146.04OUTSIDE DIAMETER275.55Baohua company was founded in 1969, from the initial initial processing to the industrial production of blank, quenching and tempering, rough machining, heat treatment, nitriding and finishing.

今連絡

Casing hanger can be divided into slip type and mandrel type. Casing hanger in oil plays an important role in fixing, supporting, sharing pressure and preventing wellbore instability, which helps to ensure the safety, stability and integrity of oil wells.MATERIAL4140-130KHARDNESS301-341INNER DIAMETER146.04OUTSIDE DIAMETER275.55Our Baohua Company was founded in 1969. After three generations' hard work, it now covers an area of 50,000 ㎡ and has a building area of 25,000 ㎡. There are 260 employees and 46 engineering technicians. The annual output of forgings is 30,000 tons.

今連絡

Baohua company was founded in 1969, from the initial initial processing to the industrial production of blank, quenching and tempering, rough machining, heat treatment, nitriding and finishing. And has ISO 9001, API 20b and API Q1 certificates.

今連絡

Hangers produced by our company are mainly used in petroleum industry. Raw materials are purchased from round steel with recognized quality at home and abroad. We can forge the corresponding model of dies and hammers according to customers' requirements, thus improving production efficiency and saving time.

今連絡

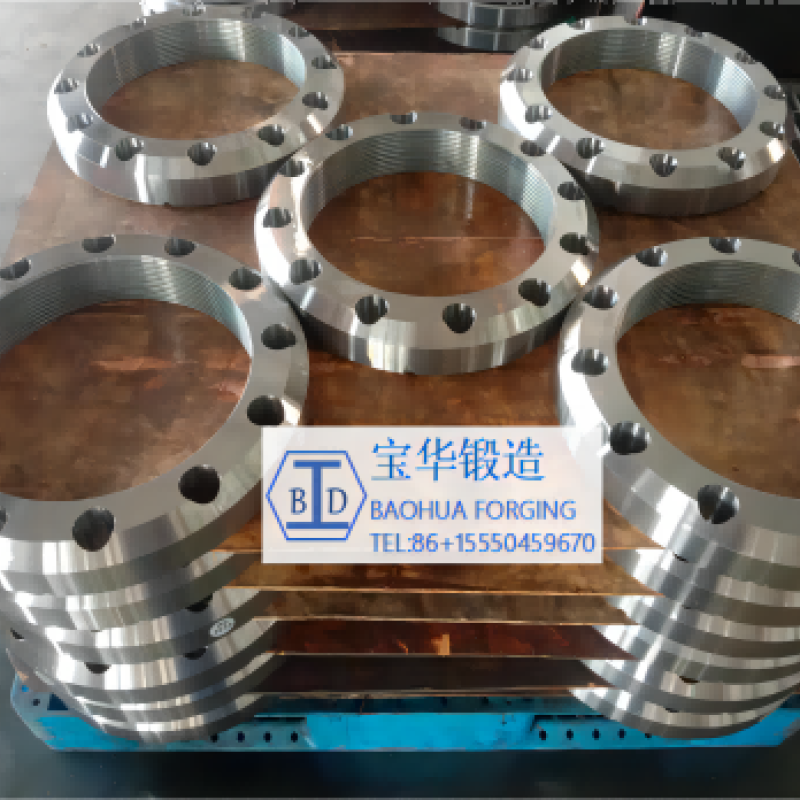

Flanges used in oil fields require strong sealing and high quality, and our Baohua company has been processing flanges in oil fields for many years and indirectly exported them to foreign countries-Germany and Russia. Because the domestic industry is not ideal, we want to import and export directly with foreign customers, avoiding third-party fees, so as to ensure high quality products and low prices. The following table is the information of this product.

今連絡

Our Baohua Company was founded in 1969. After three generations' hard work, it now covers an area of 50,000 ㎡ and has a building area of 25,000 ㎡. There are 260 employees and 46 engineering technicians. The annual output of forgings is 30,000 tons. Mainly in the automobile, hydraulic machinery, wind power generation, petroleum machinery parts, construction machinery, mining, metallurgy, shipbuilding machinery and other industries to produce related accessories. The products sold are oriented at home and abroad.

今連絡

We can make 45#, 40Cr, 30CrMo, 35CrMo, 42CrMo, 18CrNiMo7-6 and other materials according to customer requirements. According to different weights, we can forge on different forging equipment units. The weight of forged products can reach 6kg-500kg. It needs to be completed by heating, pre-forging, forming, trimming and other processes. The casing head is usually made of 35 or 42 Cr Mo alloy structural steel. There is also a casing hanger in the casing head, which is used to hang the casing string of corresponding specifications and seal the annulus. BOP stack shall be installed on it.

今連絡

We can make 45#, 40Cr, 30CrMo, 35CrMo, 42CrMo, 18CrNiMo7-6 and other materials in line with purchaser necessities. In line with one-of-a-kind weights, we can forge on exceptional forging device devices. the weight of solid merchandise can attain 6kg-500kg. it desires to be finished by using heating, pre-forging, forming, trimming and different approaches. The casing head is usually made of 35 or 42 Cr Mo alloy structural steel. A casing hanger is also arranged in the casing head to suspend casing strings of corresponding specifications and seal the annulus.

今連絡

The valve is forged in one piece, saving materials and reducing costs.Introduction: According to customer requirements, it can be made of 45#, 40Cr, 30CrMo, 35CrMo, 42CrMo, 18CrNiMo7-6 and other materials. According to different weights, it can be forged on different forging equipment units.

今連絡

According to customer requirements, it can be made of 45#, 40Cr, 30CrMo, 35CrMo, 42CrMo, 18CrNiMo7-6 and other materials. According to different weights, it can be forged on different forging equipment units. The weight of forged products can reach 6kg-500kg, Forging needs to be completed through heating, pre-forging, forming, trimming and other processes.The design of forged steel and the abrasive tools for its production require initial costs.

今連絡

According to customer requirements, it can be made of 45#, 40Cr, 30CrMo, 35CrMo, 42CrMo, 18CrNiMo7-6 and other materials. According to different weights, it can be forged on different forging equipment units. The weight of forged products can reach 6kg-500kg. Heating, pre-forging, forming, trimming and other processes are completed.Coupling refers to a device that connects two shafts or shafts and rotating parts, rotates together during the transmission of motion and power, and does not disengage under normal conditions.

今連絡

According to customer requirements, it can be made of 45#, 40Cr, 30CrMo, 35CrMo, 42CrMo, 18CrNiMo7-6, 4140, 4130 and other materials. According to different weights, it can be forged on different forging equipment units, and the weight of the forged products can reach 6kg-5000kg, forging needs to be completed through heating, pre-forging, forming and other processes.Forging is a processing method that uses forging machinery to exert pressure on metal blank to make it produce plastic deformation to obtain forgings with certain mechanical properties, certain shapes and sizes.

今連絡

Our company employs a new seamless rolled ring process to provide forged gear manufacturers with shape, size and material flexibility, lower volume requirements and near-finish shapes to save on final tooling costs. All of our forgings can go through hot die forging, rough machining, heat treatment and other processes, and the forgings can be finished to reach the final assembly condition.

今連絡

According to consumer requirements, we are able to make scrapers of numerous substances along with 45#, 40Cr, 30CrMo, 35CrMo, 42CrMo, 18CrNiMo7-6, etc. According to exclusive weights, we are able to forge on different forging system units. Our organization independently designs and manufactures molds , will maximize the financial savings of product substances and decrease forging weight, with the intention to attain price financial savings for customers.

今連絡

Our company uses the seamless rolling ring process, which makes the product more stable and can greatly reduce the weight of blanking and save cost. Forged flanges can be made of a wide range of materials including but not limited to 4140, 4130, 35CrMo, 20CrMnMO and can be forged and machined in a wide range of sizes and sizes ranging from 200mm to 3000mm in diameter.All of our forgings can be forged by hot-die forging, rough working, heat treatment and other processes, increasing the forging ratio and performance stability.

今連絡

As a mechanical part that stops or slows down the moving parts in the machine, the brake shell can be produced according to the materials required by customers in the production process. At present, our Baohua Company uses 45#, 40Cr, 30CrMo, 35CrMo, 42CrMo, 18CrNiMo7-6, etc., which are widely used. The processing of the brake shell needs to be completed by heating, pre-forging, forming, trimming and other processes. According to different weights, the forged products can be forged on different forging equipment units, and the weight of forged products can reach 6kg-500kg.

今連絡

Crankshaft is one of the main parts in machinery. Usually, it is a steel spherical rod around which wheels and other rotating parts rotate or follow. As a huge category, shafts are subdivided into intermediate shafts, crankshafts, driving shafts and so on. After the crankshaft is repeatedly pre-forged and die-forged by heating, the forging has high forging ratio, good durability and its quality is recognized by international certificates such as API API ,ISO.For details, please consult and communicate online or by email.

今連絡

As a mechanical part that stops or slows down the moving parts in the machine, the brake shell can be produced according to the materials required by customers in the production process. At present, our Baohua Company uses 45#, 40Cr, 30CrMo, 35CrMo, 42CrMo, 18CrNiMo7-6, etc., which are widely used. The processing of the brake shell needs to be completed by heating, pre-forging, forming, trimming and other processes. According to different weights, the forged products can be forged on different forging equipment units, and the weight of forged products can reach 6kg-500kg.

今連絡

For the manufacturing of Crusher Long Hammer products, our agency is capable of independently design dies and forge according to product specifications. cloth type and weight can also be produced in line with client requirements.

今連絡

Articulated joint refers to the connection point or joint between two objects or structures. Articulation joints can be made of various forms and materials, which are used to realize different types of connection functions, such as rotation, swing, fixation and so on.NAMEArticulated Joint ProductsMATERIAL42CrMoHARDNESS 235-280INNER DIAMETER210OUTSIDE DIAMETER287Our Baohua Company was founded in 1969. After three generations' hard work, it now covers an area of 50,000 ㎡ and has a building area of 25,000 ㎡. There are 260 employees and 46 engineering technicians.

今連絡

Our company is able to design dies independently and forge according to product specifications. Material type and weight can be made according to customer requirements. Our company can design the die according to the drawings provided by customers, thus realizing the precision forging, which makes the material utilization more than 90%, thus greatly saving the cost.In addition, our company also has rough machining, heat treatment and finish machining, a complete line process, and delivery according to customer requirements of different delivery status.

今連絡

For the manufacturing of flange products, our agency is capable of independently design dies and forge according to product specifications. cloth type and weight can also be produced in line with client requirements.

今連絡